Measurement and analysis of electric power on board hybrid and electric vehicles at the Joint Research Center (Ispra - Italy)

Privacy Policy

Informativa sui Cookie

The challenge

Create a versatile, robust and compact datalogger capable of measuring the signals present on the vehicle resulting from the accumulation, distribution and use of electric power both DC and AC, as well as from the control units on CAN bus, from radial sensors and GPS.

The solution

Set up the new NI CompactRIO-9068 with specific hardware modules for the signals to be acquired, developing and integrating the software components (Windows, Real-Time and FPGA) for synchronous acquisition from the various data sources.

Application

It is a widespread opinion that electric vehicles will be able to solve, or at least mitigate, the problems of pollution from motor vehicles only when new technologies are available at accessible costs to all, that is when there will be batteries with greater density of accumulation, extremely light but safe vehicles, widespread of recharging nodes, all at consumer costs comparable to the now ultra-centenarian traditional vehicles.

Meanwhile, the most widespread compromise is the hybridization of internal combustion engines, with different solutions and architectures according to the level of complexity and costs that we set ourselves as an objective, with the producers essentially divided between the inventor and those inspired by them.

Some of the most important considerations relate to the energy balance of electric vehicles as well as hybrid components in the case of synergy with heat engines, both traction and with on-board recharging (range extender), since an inefficient use of accumulated electricity translates in greater global pollution, linked to the remote production of that energy.

The research center has commissioned EURINS with a high level integration system to measure all the parameters necessary for a complete characterization on board, both on the road and on the test bench. These activities cannot be carried out using traditional laboratory instrumentation, both because it would then be necessary to unify the data coming from the individual specific instruments, and because in the road tests compactness, sturdiness and reliability are required, in addition to the same or higher quality than the instrumentation of reference.

Using the NI CompactRIO hardware platform, the NI Electrical Power Suite software library for LabVIEW and NI DIAdem, it was possible to meet all the requirements of the project, guaranteeing the quality necessary to comply with international standards for measurement and analysis of electrical power.

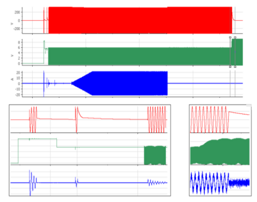

With the same system it is also possible to measure the flows of electric energy when recharging the batteries on board the vehicle when it is connected to public columns or panels for domestic use. In addition to the voltages and currents in AC or in DC depending on the products, it is particularly useful to also acquire the pilot signal that constitutes the communication protocol (handshake) between the management electronics in the vehicle and that in the recharging device. A digital line changes its level according to discrete voltage steps (0, 3, 6, 9, 12 Volt) and becomes a square wave with a variable duty cycle based on the start of the recharge, with a maximum or partial energy flow , with the batteries almost full or the cable disconnected.

Combining these measurements with all the other analogue and digital quantities, acquired in the various nodes of the vehicle where it is significant to evaluate the energy balance, constitutes a feature of absolute innovation with respect to the traditional instrumentation of industrial or laboratory derivation, with the data all available at internal of a single file, and therefore synchronous on the same basis of the times, already ready both for a quality control in the field and for in-depth analysis and report generation, thanks to the use of NI DIAdem, and MATLAB.

System Features

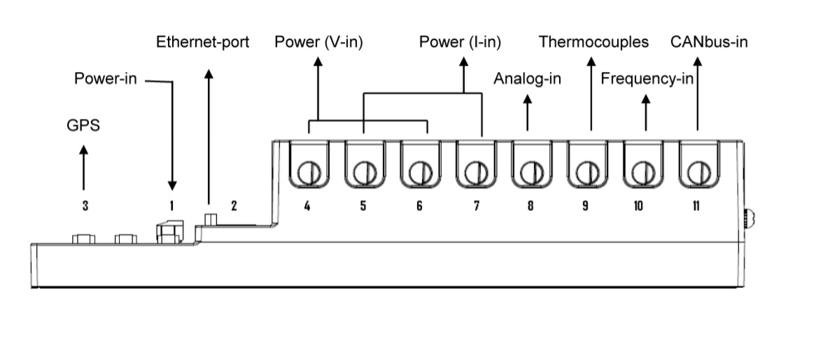

• Datalogger on NI CompactRIO platform for data acquisition and saving combined with a Windows PC connected via ethernet to configure the system, receive and analyze data

• 2 NI 9225 modules for a total of 6 simultaneous sampling differential channels (24 bits, 50 kS / s / ch, 24.6 kHz bandwidth) for voltage signals up to 300 V rms, possibility of measuring much higher voltages by means of dividers voltage and voltage transformers thanks to the use of a 24 bit A / D converter

• 2 NI 9227 modules for a total of 8 simultaneous sampling differential channels (24 bits, 50 kS / s / ch, 24.6 kHz bandwidth) for current signals up to 5 A rms, possibility of measuring much higher currents by means of transformers of current thanks to the use of a 24 bit A / D converter (ratios from "5: 5 A" to "1600: 5 A" with a resolution of 0.3 µA rms to 96 µA rms)

• 6 voltage channels and 8 current channels for power lines allow simultaneous and synchronous measurement, ie phased at FPGA level, of voltages and currents (and therefore of power and its active, reactive, apparent components, as well as harmonics, transients and current consumption according to the standard EN 50160: 2007) simultaneously on the three most neutral phases in 2 nodes of the vehicle, typically upstream and downstream of a subsystem to evaluate its efficiency in the total energy balance, or in 6 (8) single-phase distributed nodes

• Current measurements use split-core transformers or Hall-effect current clamps, so it is never necessary to interrupt the vehicle wiring.

• Measurements and calculations are standard IEC 61000-4-30: 2008 (Power frequency, Magnitude of supply voltage, Flicker (IEC 61000-4-15), Supply voltage dips and swells, Voltage interruptions, Supply voltage unbalance, Voltage harmonics (IEC 61000-4-7), Mains signaling voltage on the supply voltage, Rapid voltage changes (RVC) (IEC 61000-4-30), Sag / Swell / Interruption at standard or custom levels (IEC 61000-4-30 ), Measurement of under-deviation and over-deviation parameters)

• Acquisitions can be resampled by synchronizing to a carrier frequency, for example in the case of power measurements during recharging from a fixed installation, or using selectable sampling frequencies to digitize all the contents of interest and then analyze them both over time and in frequency

• 1 NI 9853 module with 2 high speed CAN ports and 4 NI USB-8473 modules (with 4 more high speed CAN ports available in the computer) for a total of 6 independent CAN lines that can be simultaneously read and write messages (ID 11 and 29 bits, baud rate up to 1 Mbps) according to the DBC, OBD, FMS, J1939 standards with the availability of an editor for creating personalized messages to interpret unencoded flows

• 1 GPS receiver (NMEA standard) for continuous acquisition of the geographical position, direction, absolute time and speed with respect to the ground

Conclusions

The system is destined to further developments to be ever more complete and effective, following what will be the new measurement requirements and the new investigation objectives.

The electrification of traction in vehicles will involve state-of-the-art technologies for batteries, cables, electric motors, inverters and management devices, so it will be increasingly necessary to combine measurements on board on all components, both traditional and innovative, to get reliable information quickly.

Privacy Policy

Informativa sui Cookie